Address

Head Quartered: A3, Dubai World Central, Dubai South, UAE

Factory: Umm Dera – New Industrial Area – Umm Al Quawain

Corporate Office: Street 10, Al Quoz Industrial Area 4, Dubai, UAE

Work Hours

Monday to Friday: 8AM - 7PM

Weekend: 10AM - 5PM

Address

Head Quartered: A3, Dubai World Central, Dubai South, UAE

Factory: Umm Dera – New Industrial Area – Umm Al Quawain

Corporate Office: Street 10, Al Quoz Industrial Area 4, Dubai, UAE

Work Hours

Monday to Friday: 8AM - 7PM

Weekend: 10AM - 5PM

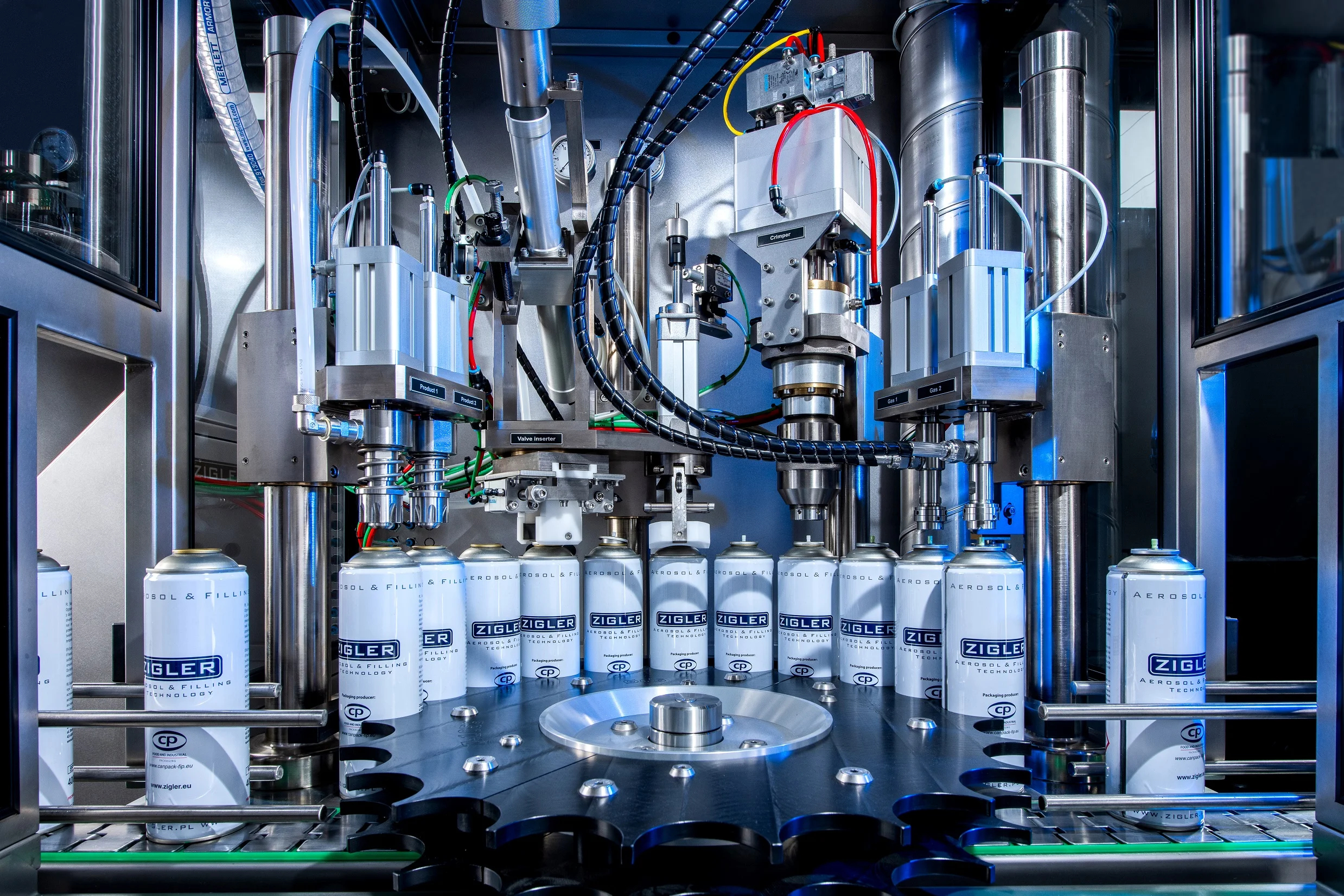

ASPC Aerosols deliver high performance aerosol products through state of the art automation, a “Today Not Tomorrow” (TNT) culture and a truly client-focused methodology.

The company has been built upon the solid foundation and philosophy of rationalised key product ranges, the highest quality standards, and the shortest lead times. These key elements are embedded in the fabric of the business and continue to be a core element of what makes ASPC Aerosols the success it is today.

ASPC Aerosols currently occupies a 50,000 square foot manufacturing site, split across three independent production lines, able to fill a wide portfolio of aerosols meeting customer demand across a multitude of sectors.

“ASPC continually challenges our engineers to solve complex customer problems, we expect a challenge and normally get one!” Key valve supplier

“Having worked with APCS for over 10 years, our opportunities to develop new products for our emerging markets is unrivaled. We look forward to another 10 years of AFT supplying our European sites” Multi-national adhesives and sealants manufacturer.

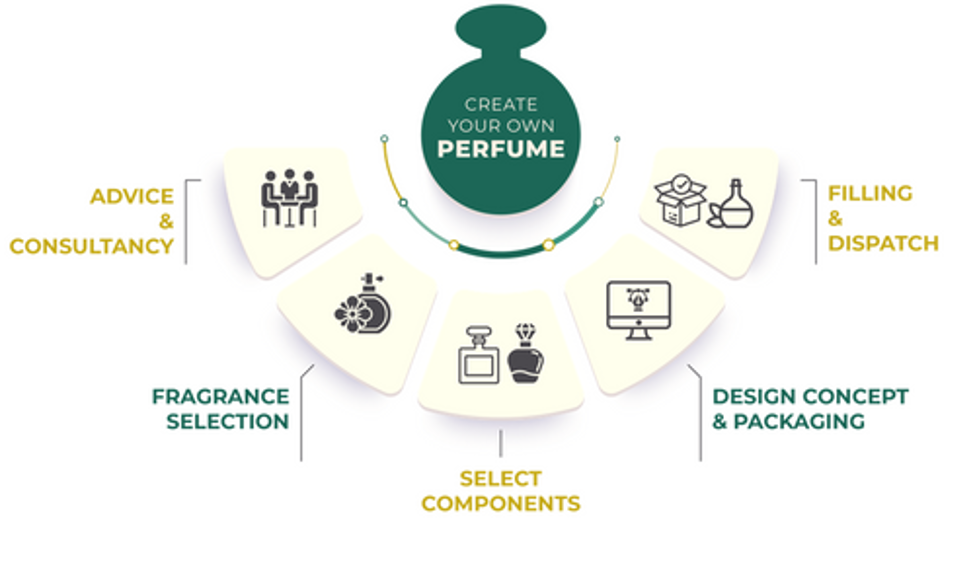

This is the initial phase of our engagement where we provide consultancy in making your own perfume. As per your requirement, we offer advice on the budget, quality, and time required to launch.

We have a huge collection of fragrances to choose from. However, if you need a very unique blend of fragrance oils, our perfumers are experts at this. We also test these fragrances on our skin as well as fabrics for longevity.

The bottle, the pump, and the cap; the key elements of your product design. We have consolidated a list of perfume-making components, suppliers, and prices. For large quantities, we also place orders from China and other countries worldwide.

We have specialist product designers who can work with you to create enticing designs and make physical mock-ups of your product before the manufacturing process. They will re-work different aspects of the design until your approval.

Next is purely a labor-oriented job at the factory where your product is actually made. Based on the quantities that you have specified it would take anywhere between one week to one month. Your product is manufactured alongside a quality assurance team that performs quality audit processes like monitoring, compliance, and release.

Some feedback from our clients

Aenean sed nibh a magna posuere tempor faucibus pellentesque in aliquet congue tempor conguenim.

Nunc purus est, consequat condimentum faucibus sed, iaculis sit amet massa fusce ac condimentum.

Aenean sed nibh a magna posuere tempor faucibus pellentesque in aliquet congue tempor conguenim.